銅パイプのろう付け方法は、多くのろう付け職人が考えてきた問題です。水道用銅パイプの使用は紀元前2150年までさかのぼります。今日、銅パイプはあらゆる空調設備や給湯設備に使われています。その理由は?銅は無毒で、不浸透性、耐久性、柔軟性があり、水道配管のニーズには理想的な組み合わせです。

銅パイプは流体を運ぶため、機械的に固定することはできません。銅パイプのろう付けは、漏れのない接合部を得るための最良の解決策です。ろう付けでは、パイプを連結して高温で加熱し、フィラーメタルを溶かします。

溶融プロセスには、直火技術や誘導ろう付けのような火を使わない方法など、さまざまな方法があります。この記事では、銅パイプをロウ付けする3つの主要な方法について、それぞれの設備と詳細な手順について説明します。

Method 1: Brazing Copper with a Torch

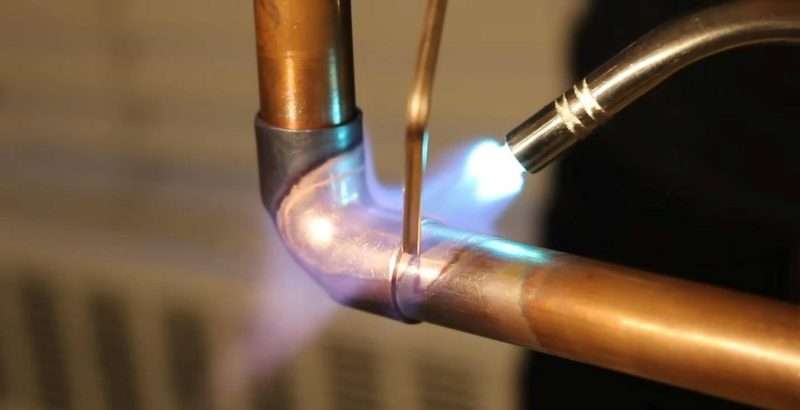

This is the traditional way of brazing copper, common for small-scale HVAC jobs. In this method, a direct flame (typically from an oxy-acetylene or propane torch) heats the joint area. The higher temperature (around 1300 to 1500°F ) melts the filler metal, which is then drawn into the joint by capillary action.

Remember, the temperature is high but not enough to melt the base metal (copper); instead, it liquefies only the filler to form a strong, leak-proof bond. A flux may also be applied before heating to prevent oxidation of the metals.

Tools Needed

The torch brazing process requires these supplies and tools:

- Flame Torch – Acetylene or propane

- Filler Rod – Phosphorus copper (BCuP) for copper-to-copper pipes and silver-based (BAg) for mixed metals.

- Flux (Optional): Borax-based

- Cleaning Brush/Emery Cloth, Sandpaper

- Pipe Cutter, Deburring Tool

- Igniter or Lighter

How to Braze Copper Pipes with a Torch

To braze copper pipe with a flame torch, here’s a more structured approach, with all detailed insights gathered from expert technicians:

Step 1: Cut and Clean

First, use a pipe cutter to cut the copper pipe to the desired length. Use a deburring tool to get rid of any cutting burs on the edges.

Clean the mating surfaces with a wire brush or emery cloth until they shine. Any dirt, grease, or oxidation will hinder the bond.

Step 2: Apply Flux (Optional)

Apply flux to both the pipe and fitting using a brush (optional for copper-to-copper brazing, but required for other metal combinations). Then, join the loose ends of the pipe and fitting.

ステップ3:トーチで加熱する

トーチに火をつけ、中性の炎(酸化しすぎず、還元しすぎず)に調整する。銅を均一に加熱するため、ジョイントの周囲に炎を均等に動かします。まず底を熱し、それからゆっくりと側面全体を覆う。

ステップ4:フィラーを加える

パイプが十分に熱くなったら(赤くなったら)、フィラーロッドを接合部に当てる。フィラー・ロッドを炎で直接溶かさないでください。その代わり、パイプの熱でフィラーを溶かし、毛細管現象でジョイントに流れ込ませる。継ぎ目の周囲でロッドを回転させ、均等に行き渡るようにする。

Step 5: Cool and Clean

Allow the joint to cool naturally; using a wet rag too soon can cause cracks. After it’s cooled, inspect the joint for gaps or weak spots. Wipe off excess flux (if used) to prevent corrosion over time.

Method 2: Induction Brazing

Induction brazing is a modern, flame-free method that uses electromagnetic induction to heat the joint. An alternating magnetic field, generated by an induction coil, induces eddy currents in the copper pipe, heating it to the required temperature. The filler metal, pre-placed as a ring or wire, melts and flows into the joint without direct contact with a flame.

Tools Needed

- Cleaning Brush/Sandpaper

- Induction Heater

- Filler Rings/Rod

How to Induction Braze Copper Pipes

Step 1: Cut and Clean

The induction brazing process for copper pipes requires similar cleaning steps as torch brazing. You’ll first need to clean the joint with a wire brush or sandpaper. The next steps are:

Step 2: Prepare an Overlap Joint

Apply flux, if mating copper pipe with another joint. For copper-to-copper pipe joints, you can skip the fluxing. Create a lap joint between the two pipes. The American Welding Society recommends that the overlapping must be 3x the pipe thickness for an optimal joint. If you’re going to use filler rings, they have to be applied in this step.

Step 3: Assemble and Clamp

Since the joints are loose before brazing, a clamp setup is required to temporarily hold them in place for the induction brazing operation.

ステップ4:インダクター・ヒーターで加熱し、フィラーを塗布する

Place the clamped joint inside the induction coil setup such that the joint is fully surrounded. If a portable coil is being used, hold it near the joint. Turn it on for 5 to 10 seconds, until the pipes get red hot.

If filler rings are in place, they’ll melt and infuse the gaps. If using filler rod, rotate the rod around the join slowly so that it melts and moves inside.

Step 5: Cool and Clean

Allow the joint to cool and clean it before usage.

Method 3: Controlled Atmosphere Brazing/Furnace Brazing

Controlled atmosphere brazing (CAB) is a process where brazing is performed in a sealed furnace filled with an inert or reducing gas (e.g., nitrogen or hydrogen). The atmosphere prevents oxidation and contamination, which produces stronger and cleaner joints.

This process is common for batch-brazing aluminum heat exchangers in the auto industry. It’s also suitable for critical copper applications, for instance, x-ray tubes, wave tubes, and linear accelerators.

Tools Needed:

- Cleaning Tools

- Furnace

- Filler Rings

- Inert Gas

How to Perform Furnace Brazing

CAB requires a closed furnace to take place, limiting its use to industries. Here’s an overview of the process.

Step 1: Cleaning

The parts need thorough cleaning. That can be done via simple brushing, or they may undergo solvent baths.

Step 2: Filler Application

The filler metal is applied in the form of pre-shaped rings or washers. It is positioned such that when the pipes get heated, the filler melts and infuses inside of the joint.

Step 3: Transport to Furnace

The prepared parts are loaded onto conveyor belts for transport into the furnace. Fixtures may be used to hold the components in precise alignment during the brazing process.

Step 4: Heating

The furnace is purged with an inert or reducing gas to remove oxygen and create a controlled atmosphere. The temperature is ramped up to a point (about 1300°F ) where filler starts to melt and flow into the joint.

Step 5: Cooling

The parts are slowly cooled down to avoid cracking and the development of stresses.

How to Choose the Right Method for Brazing Copper Pipes

We’ve listed three methods, but you can only go with one. So, to choose, we want you to keep in mind a few considerations like your joint size, operating environment, budget constraints, and skill level.

Joint Size/Geometry

Each technique excels in specific joint cases. Among the techniques, torch brazing is quite versatile – it can handle large, irregular, or hard-to-reach joints, such as those found in HVAC systems or plumbing repairs. Due to its manual scale, it’s easy to make adjustments on the fly.

Induction brazing excels with small and standardized joint diameters. This method is limited to geometries that fit within the induction coil, or a custom joint has to be made. Still, it’s a great option for HVAC piping.

Furnace brazing is best suited for medium to large batches of components with consistent joint designs.

Environment

The external factors also have a role in method usage. Torch brazing is well-suited for fieldwork or repairs but should be avoided in confined, flammable, or oxygen-sensitive spaces due to the open flame.

Induction brazing, on the other hand, is a flame-free option and can be freely used indoors in cleanrooms, hospitals, or explosive atmospheres.

Furnace brazing is an industry-limited option.

Budget

Torch brazing setup is comparatively less complex and cheaper than the other techniques. But if we consider safety as well as affordability, portable induction brazing equipment is a good option. Furnace brazing has an expensive setup, but that’s viable when you need to batch product parts.

Skill Level

Torch brazing demands advanced manual skills, including precise flame control and timing when feeding the filler metal. Mistakes, such as overheating or uneven heating, can lead to weak joints.

CAB is also technically demanding as it requires knowledge of furnace operation, gas management, and thermal cycles. It’s typically used by trained professionals in industrial settings.

Among the three, induction brazing requires the most minimal operator expertise once the system is programmed, making it accessible for workers with basic training.

Choose FOCO Induction Equipment for Brazing Copper Pipes

If you’re convinced that induction heating is the ideal solution for your brazing needs, we recommend exploring FOCO’s lineup of induction heating systems.

Our range includes portable units for small-scale operations and robust industrial systems designed for high-volume production. With frequency options ranging from 1 kHz to 800 kHz and power outputs from 6 kW to 200 kW, FOCO equipment is engineered to meet diverse brazing requirements.

Contact us today to discuss your specific needs, and let our experts guide you in selecting the perfect induction heating solution.