Cómo soldar tuberías de cobre es una pregunta que muchos soldadores se han planteado. El uso de tuberías de cobre para el suministro de agua se remonta al año 2150 a.C. Hoy en día, estas tuberías se encuentran en todos los sistemas de calefacción, ventilación y agua caliente. ¿El motivo? El cobre no es tóxico, es impermeable, duradero y flexible: la combinación ideal para las necesidades de conducción de agua.

Como las tuberías de cobre transportan fluidos, no pueden fijarse mecánicamente. La soldadura fuerte de tuberías de cobre es la mejor solución para conseguir uniones a prueba de fugas. En la soldadura fuerte, los tubos se acoplan y se calientan a altas temperaturas, fundiendo el metal de aportación, que luego se fusiona en el interior para crear una unión permanente.

El proceso de fusión puede conseguirse de distintas formas, mediante técnicas de fuego directo u opciones sin fuego, como la soldadura por inducción. Este artículo explora tres métodos clave para soldar tubos de cobre, mencionando el equipo y los pasos detallados de cada uno.

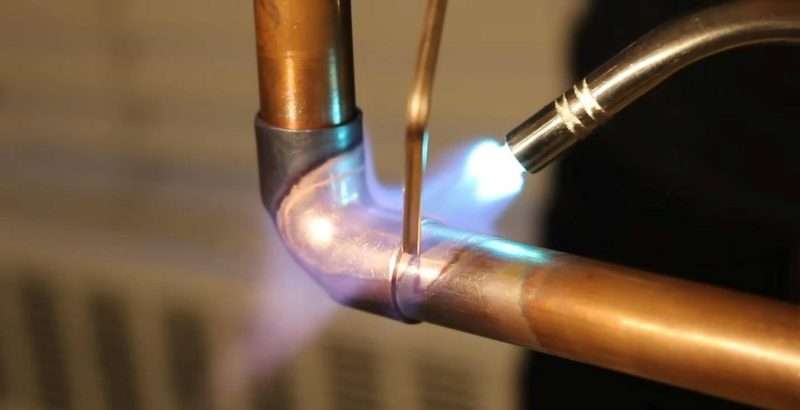

Method 1: Brazing Copper with a Torch

This is the traditional way of brazing copper, common for small-scale HVAC jobs. In this method, a direct flame (typically from an oxy-acetylene or propane torch) heats the joint area. The higher temperature (around 1300 to 1500°F ) melts the filler metal, which is then drawn into the joint by capillary action.

Remember, the temperature is high but not enough to melt the base metal (copper); instead, it liquefies only the filler to form a strong, leak-proof bond. A flux may also be applied before heating to prevent oxidation of the metals.

Tools Needed

The torch brazing process requires these supplies and tools:

- Flame Torch – Acetylene or propane

- Filler Rod – Phosphorus copper (BCuP) for copper-to-copper pipes and silver-based (BAg) for mixed metals.

- Flux (Optional): Borax-based

- Cleaning Brush/Emery Cloth, Sandpaper

- Pipe Cutter, Deburring Tool

- Igniter or Lighter

How to Braze Copper Pipes with a Torch

To braze copper pipe with a flame torch, here’s a more structured approach, with all detailed insights gathered from expert technicians:

Step 1: Cut and Clean

First, use a pipe cutter to cut the copper pipe to the desired length. Use a deburring tool to get rid of any cutting burs on the edges.

Clean the mating surfaces with a wire brush or emery cloth until they shine. Any dirt, grease, or oxidation will hinder the bond.

Step 2: Apply Flux (Optional)

Apply flux to both the pipe and fitting using a brush (optional for copper-to-copper brazing, but required for other metal combinations). Then, join the loose ends of the pipe and fitting.

Paso 3: Utiliza el soplete para calentar

Enciende el soplete y ajústalo a una llama neutra (no demasiado oxidante ni reductora). Mueve la llama uniformemente alrededor de la junta para calentar el cobre de manera uniforme. Calienta primero la parte inferior y luego cubre lentamente todos los lados.

Paso 4: Añadir relleno

Cuando el tubo esté lo suficientemente caliente (se pone rojo), toca la junta con la varilla de relleno. No derritas la varilla de relleno directamente con la llama. En lugar de eso, deja que el calor de la tubería funda la masilla y permita que fluya hacia la junta por capilaridad. Gira la varilla alrededor de la junta para asegurar una cobertura uniforme.

Step 5: Cool and Clean

Allow the joint to cool naturally; using a wet rag too soon can cause cracks. After it’s cooled, inspect the joint for gaps or weak spots. Wipe off excess flux (if used) to prevent corrosion over time.

Method 2: Induction Brazing

Induction brazing is a modern, flame-free method that uses electromagnetic induction to heat the joint. An alternating magnetic field, generated by an induction coil, induces eddy currents in the copper pipe, heating it to the required temperature. The filler metal, pre-placed as a ring or wire, melts and flows into the joint without direct contact with a flame.

Tools Needed

- Cleaning Brush/Sandpaper

- Induction Heater

- Filler Rings/Rod

How to Induction Braze Copper Pipes

Step 1: Cut and Clean

The induction brazing process for copper pipes requires similar cleaning steps as torch brazing. You’ll first need to clean the joint with a wire brush or sandpaper. The next steps are:

Step 2: Prepare an Overlap Joint

Apply flux, if mating copper pipe with another joint. For copper-to-copper pipe joints, you can skip the fluxing. Create a lap joint between the two pipes. The American Welding Society recommends that the overlapping must be 3x the pipe thickness for an optimal joint. If you’re going to use filler rings, they have to be applied in this step.

Step 3: Assemble and Clamp

Since the joints are loose before brazing, a clamp setup is required to temporarily hold them in place for the induction brazing operation.

Paso 4: Calentar con calentador inductor y aplicar masilla

Place the clamped joint inside the induction coil setup such that the joint is fully surrounded. If a portable coil is being used, hold it near the joint. Turn it on for 5 to 10 seconds, until the pipes get red hot.

If filler rings are in place, they’ll melt and infuse the gaps. If using filler rod, rotate the rod around the join slowly so that it melts and moves inside.

Step 5: Cool and Clean

Allow the joint to cool and clean it before usage.

Method 3: Controlled Atmosphere Brazing/Furnace Brazing

Controlled atmosphere brazing (CAB) is a process where brazing is performed in a sealed furnace filled with an inert or reducing gas (e.g., nitrogen or hydrogen). The atmosphere prevents oxidation and contamination, which produces stronger and cleaner joints.

This process is common for batch-brazing aluminum heat exchangers in the auto industry. It’s also suitable for critical copper applications, for instance, x-ray tubes, wave tubes, and linear accelerators.

Tools Needed:

- Cleaning Tools

- Furnace

- Filler Rings

- Inert Gas

How to Perform Furnace Brazing

CAB requires a closed furnace to take place, limiting its use to industries. Here’s an overview of the process.

Step 1: Cleaning

The parts need thorough cleaning. That can be done via simple brushing, or they may undergo solvent baths.

Step 2: Filler Application

The filler metal is applied in the form of pre-shaped rings or washers. It is positioned such that when the pipes get heated, the filler melts and infuses inside of the joint.

Step 3: Transport to Furnace

The prepared parts are loaded onto conveyor belts for transport into the furnace. Fixtures may be used to hold the components in precise alignment during the brazing process.

Step 4: Heating

The furnace is purged with an inert or reducing gas to remove oxygen and create a controlled atmosphere. The temperature is ramped up to a point (about 1300°F ) where filler starts to melt and flow into the joint.

Step 5: Cooling

The parts are slowly cooled down to avoid cracking and the development of stresses.

How to Choose the Right Method for Brazing Copper Pipes

We’ve listed three methods, but you can only go with one. So, to choose, we want you to keep in mind a few considerations like your joint size, operating environment, budget constraints, and skill level.

Joint Size/Geometry

Each technique excels in specific joint cases. Among the techniques, torch brazing is quite versatile – it can handle large, irregular, or hard-to-reach joints, such as those found in HVAC systems or plumbing repairs. Due to its manual scale, it’s easy to make adjustments on the fly.

Induction brazing excels with small and standardized joint diameters. This method is limited to geometries that fit within the induction coil, or a custom joint has to be made. Still, it’s a great option for HVAC piping.

Furnace brazing is best suited for medium to large batches of components with consistent joint designs.

Environment

The external factors also have a role in method usage. Torch brazing is well-suited for fieldwork or repairs but should be avoided in confined, flammable, or oxygen-sensitive spaces due to the open flame.

Induction brazing, on the other hand, is a flame-free option and can be freely used indoors in cleanrooms, hospitals, or explosive atmospheres.

Furnace brazing is an industry-limited option.

Budget

Torch brazing setup is comparatively less complex and cheaper than the other techniques. But if we consider safety as well as affordability, portable induction brazing equipment is a good option. Furnace brazing has an expensive setup, but that’s viable when you need to batch product parts.

Skill Level

Torch brazing demands advanced manual skills, including precise flame control and timing when feeding the filler metal. Mistakes, such as overheating or uneven heating, can lead to weak joints.

CAB is also technically demanding as it requires knowledge of furnace operation, gas management, and thermal cycles. It’s typically used by trained professionals in industrial settings.

Among the three, induction brazing requires the most minimal operator expertise once the system is programmed, making it accessible for workers with basic training.

Choose FOCO Induction Equipment for Brazing Copper Pipes

If you’re convinced that induction heating is the ideal solution for your brazing needs, we recommend exploring FOCO’s lineup of induction heating systems.

Our range includes portable units for small-scale operations and robust industrial systems designed for high-volume production. With frequency options ranging from 1 kHz to 800 kHz and power outputs from 6 kW to 200 kW, FOCO equipment is engineered to meet diverse brazing requirements.

Contact us today to discuss your specific needs, and let our experts guide you in selecting the perfect induction heating solution.