Aluminum alloy melting is the essential first step in creating countless products we rely on daily. Think about cars, airplanes, smartphones, or even packaging—many components start as molten aluminum.

This process transforms solid metal into a liquid state, ready for shaping into final forms through casting or other methods. It sounds straightforward, right?

However, successfully melting aluminum alloys involves careful control. Key factors like temperature precision and preventing contamination are absolutely critical.

Furthermore, different aluminum alloys have unique melting points and behaviors. Getting this step wrong can lead to weak spots, unwanted impurities, or even safety hazards later on.

Thankfully, modern melting technology provides smart solutions. Techniques like using protective gases and electromagnetic stirring help maintain quality and efficiency. Understanding these basics empowers manufacturers and designers to make better choices.

In the next sections, we’ll explore exactly how controlled melting works and why it matters so much for producing high-performance aluminum parts. Stay tuned.

What is Aluminum Alloy?

Simply put, aluminum alloy is aluminum strengthened by adding other elements. Pure aluminum is soft and weak. But by mixing in small amounts of metals like copper, magnesium, silicon, manganese, or zinc, we can enhance its properties. The resulting materials have vastly improved strength, hardness, or other special characteristics. These mixtures are aluminum alloys.

Two Main Families: Wrought vs. Cast

First, it’s crucial to understand the two big families based on how we shape them:

- Wrought Alloys: These get their final shape through mechanical working—think rolling, pressing, or extruding them while solid. Imagine squeezing or stretching the metal.

- Cast Alloys: These start life by pouring molten metal directly into a mold. The liquid metal fills the mold cavity and solidifies into the desired shape, often complex.

Learn more about Wrought and Cast Aluminum Alloys Designations.

Wrought Alloy

Each series, identified by its first number, has a dominant alloying element and unique traits:

- 1xxx Series (Pure Specialist): Over 99% pure aluminum. Top choice for electrical lines, heat exchangers, and tanks thanks to unmatched conductivity and corrosion resistance. Relatively weak.

- 2xxx Series (Strong Flyer): Copper-based. Delivers high strength/hardness after heat treatment. Requires protection for corrosion and is tough to weld. Essential for aircraft structures.

- 3xxx Series (Forming Pro): Manganese is key. Loved for its easy forming, welding, and corrosion resistance (think beverage can bodies!). Moderate strength.

- 5xxx Series (Marine Guardian): Magnesium-rich. Offers good weldability and exceptional seawater corrosion resistance. Doesn’t strengthen via heat treatment. Dominates ships and marine hardware.

- 6xxx Series (Balanced MVP): Magnesium + Silicon. The go-to alloy! Balances good, heat-treatable strength with excellent formability, weldability, and corrosion resistance. Everywhere—from windows to cars.

- 7xxx Series (Ultra-Strong): Zinc + Magnesium/Copper. The strongest heat-treatable alloys. It requires extra attention because it resists corrosion less and proves tougher to machine. Essential for vital airplane components and high-end athletic equipment.

The Casting Alloys

For parts needing complex shapes made directly from molten metal, cast alloys step in. Among these, the Al-Si series (like common grades A356 or A380) reigns supreme.

Their superpower is superb fluidity when molten, allowing them to fill intricate molds easily. Strength ranges from moderate to high depending on the specific alloy. Manufacturers commonly choose these alloys for building engine blocks, transmission housings, wheels, and power tool casings.

Now that we’ve met the key players in the aluminum alloy family and seen what they can do, the next question is, how do we actually make these alloys ready for shaping?

This is where the crucial process of melting comes in. Getting the melting step right is fundamental to unlocking the performance potential we just described for each alloy type. Let’s explore how it works

How is Aluminum Alloy Melted?

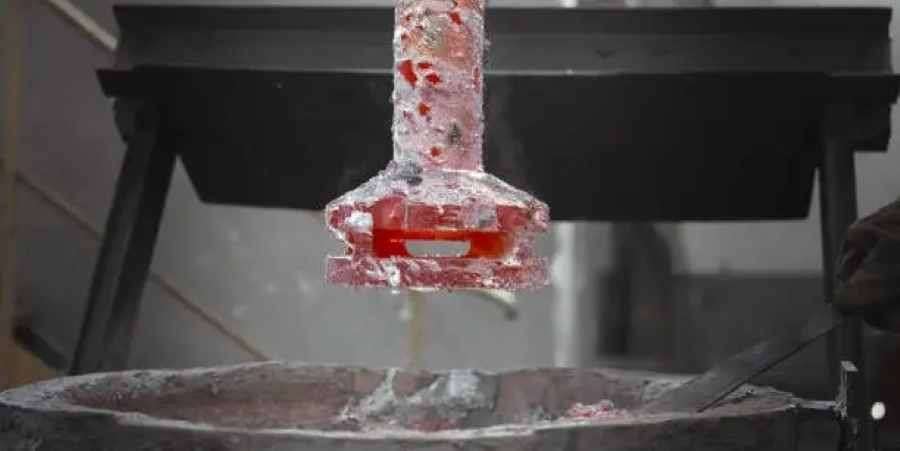

Melting isn’t just about turning solid metal liquid. For aluminum alloys, the core goals are clear. First, we need molten metal with the exact chemical composition. Second, it must have minimal impurities and low dissolved gas—especially hydrogen. Finally, the material must achieve perfect uniformity.

Get this right, and the final cast or shaped product performs reliably. Get it wrong, and defects like pores, weak spots, or cracks can appear later. So, how do we control the melt?

Preparing the Ingredients

Think of this as gathering quality ingredients for a recipe. We use either:

- Primary Aluminum: New aluminum ingots from electrolysis.

- Recycled Scrap: Shredded and meticulously cleaned aluminum scrap. Proper sorting here is vital to avoid contaminants!

Crucially, we add alloying elements like magnesium, silicon, or copper not as pure metals, but usually as master alloys (a pre-made Al-X alloy). Why? Because they melt easier, dissolve faster, and we lose less metal to oxidation (“burn-off”).

Loading the Furnace

How you pile the metal into the furnace impacts melt quality and efficiency. Here’s the smart order:

- Protective Layer: Small scrap pieces or protective fluxes might go in first to shield the furnace bottom.

- Bulk Load: Big solid ingots or heavy scrap chunks go next.

- Tricky Alloys: Add hard-to-melt elements (like certain master alloys).

- Sensitive Elements: Finally, add easily oxidized or volatile elements like magnesium or zinc after the main bath forms, minimizing losses.

Melting & Temperature Control

We melt aluminum in furnaces like gas-fired reverberatory furnaces or efficient induction furnaces. The target temperature range is usually 700°C to 760°C, depending heavily on the specific alloy. Critical: Avoid overheating! Higher temperatures mean:

- More oxygen absorption → More oxide impurities.

- More hydrogen gas dissolving → Leads to porosity later.

- More energy waste and unwanted metal burn-off.

Mixing in the Good Stuff

Once the main aluminum bath is liquid, we introduce the master alloys or pure elements needed for the specific recipe. Vigorous mechanical stirring or rotary degassing (which also stirs) immediately follows.

This step is non-negotiable! It ensures the additives dissolve completely and distribute evenly throughout the entire melt. Without it, you get “segregation“–heavy elements like copper sinking, leaving weak zones.

Degassing & Fluxing

This step tackles dissolved hydrogen gas and solid impurities (oxides, salts, bits of refractory).

- Degassing: We inject a fine stream of inert gases (like argon or nitrogen), or sometimes specialized mixes, deep into the melt. As the bubbles rise, they act like tiny magnets, pulling dissolved hydrogen out of the liquid aluminum and carrying it away. Some advanced systems use ultrasound instead.

- Fluxing: Adding specific chemical fluxes helps in several ways:1) They form a protective cover layer, blocking air contact. 2) They react with oxides and salts, dissolving or trapping them. 3) They help clump fine impurities together, making them easier to remove. The impurities either rise to the top (forming “dross”) or sink to the bottom for removal.

Composition Testing & Adjustment

Even with careful preparation, chemistry can drift. We take a small sample and perform a super-fast spectral analysis (OES—Optical Emission Spectroscopy). This gives precise element levels in minutes.

Based on this, we calculate and add any tiny missing amounts of alloying elements, then quickly remelt and stir them in. Often, a final quick spectral check confirms we nailed it.

Holding & Transfer

Finally, the purified melt is adjusted to its optimal casting temperature (different from melting temperature!) and held there briefly under protective cover.

Then, it’s quickly moved—usually via a sealed launder system or pressurized crucible—to the casting machine or mold. Speed here minimizes reabsorption of gases or formation of oxides.

While these core steps form the backbone, the specific requirements vary significantly. They depend on whether we’re melting a sensitive aerospace 2xxx alloy, a recyclable 3xxx can body alloy, or a high-silicon casting alloy. Each family demands specific tweaks to temperatures, gas mixtures, fluxes, and handling procedures!

Strategies for Different Aluminum Alloys

Melting aluminum isn’t one-size-fits-all! High-magnesium alloys (5xxx) fight oxidation fiercely. 2xxx series alloys with high copper content require strong mixing to prevent sinking and additional gas removal for hydrogen.

Versatile 6xxx alloys require precise silicon temperature control. Ultra-strong 7xxx alloys demand strict purity. Casting alloys focus on fluidity. Specific strategies ensure quality for each type’s unique “personality.”

Melting High-Magnesium Alloys (5xxx Series)

Melting alloys rich in magnesium, like the popular 5xxx series, brings a specific challenge: fierce oxidation.

Magnesium readily bonds with oxygen, creating a rough, crusty layer (MgO) that captures usable metal and thickens the molten mixture. This dross also reduces quality. Therefore, specialized strategies are essential.

First, using the right flux is non-negotiable. We need powerful fluxes that create an excellent protective cover, block air contact, and actively remove existing oxides.

Second, never add pure magnesium metal directly. Instead, we always use premade Al-Mg master alloys. These dissolve easier and significantly reduce magnesium’s exposure time to air, minimizing losses.

Furthermore, timing and temperature are critical. We add the Al-Mg master alloy late, after the main aluminum bath is molten. Also, we keep the melting and holding temperatures as low as practically possible. Higher heat just speeds up oxidation.

Finally, stirring must be effective but gentle. Vigorous stirring that churns the surface exposes fresh metal to air, creating more dross.

Controlled stirring ensures mixing without excessive oxidation. For critical applications, melting under a protective inert gas atmosphere (like argon) adds an extra safety layer against magnesium loss and dross formation.

Melting High-Copper Alloys (2xxx Series)

Achieving a uniform, high-quality melt for copper-rich 2xxx aerospace alloys requires tackling two key issues: copper segregation and extreme hydrogen sensitivity.

Copper is significantly heavier than aluminum. If not managed, it tends to sink towards the bottom of the melt pool, leading to uneven composition (segregation).

Therefore, powerful stirring is mandatory. We use powerful mechanical or electromagnetic stirring to maintain full dissolution of copper. The mixing power needs to fully blend all components evenly across the whole molten mixture. Without this, weak spots can form in the final product.

Additionally, 2xxx alloys are notorious for easily absorbing hydrogen gas, which leads to severe porosity (holes) and shrinkage issues during solidification. Consequently, degassing needs extra attention.

We extend the gas purging time or increase the gas flow rate compared to other alloys. Using reliable inert gases like argon or nitrogen is standard practice. Monitoring the melt density or using specialized hydrogen sensors helps confirm we’ve removed enough gas.

Similar to magnesium processing, we prefer using Al-Cu master alloys rather than pure copper. This ensures more controlled dissolution and better melt uniformity before casting these critical aerospace components.

Melting High-Zinc/Magnesium Alloys (7xxx Series)

Melting the super-strong 7xxx series presents distinct hurdles. The main issue is zinc and magnesium volatility; they readily vaporize at typical melting temperatures, causing visible fumes and significant metal loss (“fuming”).

Furthermore, some standard fluxes can actually corrode these sensitive elements. To counter this, strict temperature control is paramount—we melt at the lowest practical temperature to minimize vaporization.

Crucially, we only use Al-Zn and Al-Mg master alloys, not pure metals, for safer, more controlled dissolution. Selecting the right flux is also vital; we need specially formulated, low-corrosion options and carefully control the amount used.

Finally, adding the Zn/Mg master alloys late in the process, after the base aluminum is molten, reduces their exposure time and minimizes losses.

Melting High-Silicon Casting Alloys (A356, A380)

High-silicon casting alloys like A356 and A380 are workhorses for complex shapes, but their melting introduces specific hurdles. The biggest challenge is modification control.

Adding elements like Sodium (Na) or Strontium (Sr) refines the silicon structure, crucial for strength and ductility. However, these modifiers are incredibly reactive. They oxidize rapidly, and their effectiveness fades quickly over time.

Consequently, precise timing is vital—modifiers are added very late, often just minutes before casting, and injected under a protective cover gas or flux layer to maximize uptake.

A second major concern is iron (Fe) contamination. Iron enters easily from recycled scrap, tools, or furnace linings. Even small amounts form hard, brittle intermetallic phases, severely reducing toughness and machinability.

Combating this requires stringent control of scrap Fe levels and using specialized fluxes or additives containing Manganese (Mn). Mn helps modify the Fe phases into less harmful forms, partially mitigating its negative impact.

Thirdly, these alloys are notorious for generating copious, sticky dross. The high silicon content promotes thick oxide formation. This requires highly effective dross removal agents capable of breaking down viscous slag.

These must be combined with disciplined, frequent skimming practices during both melting and holding stages. Efficient dross control minimizes melt loss and prevents slag inclusions in castings.

Melting High-Purity Aluminum (1xxx Series)

Melting high-purity aluminum is fundamentally about preserving extreme purity, especially concerning trace elements like Iron, Silicon, and Copper. Even minute levels of these contaminants drastically degrade the alloy’s star properties—exceptional electrical conductivity and corrosion resistance.

Prevention is the absolute priority. This starts with rigorous raw material selection: only high-grade primary aluminum ingots or meticulously sorted, certified high-purity scrap are used.

Crucially, dedicated melting equipment is essential. Separate furnaces or, more commonly, dedicated ceramic-lined crucibles reserved only for high-purity melts are standard practice. This prevents cross-contamination from residues of other alloys containing Fe, Cu, or Si that might linger in a shared furnace.

Refining practices also needs careful adjustment. While degassing to remove hydrogen is still necessary, it must be done gently using ultra-clean, dry inert gases like argon. Aggressive degassing or using reactive gases (like chlorine) risks introducing impurities.

Similarly, fluxing, if used at all, requires minimal quantities of specialized high-purity fluxes designed to leave minimal residue. The entire process emphasizes minimizing any interaction that could add trace elements.

Temperature control remains crucial to avoid overheating, but our primary focus is safeguarding the melt’s inherent purity. From the moment solid metal enters the crucible, we implement strict process controls. These are maintained through pouring to ensure the final product meets stringent conductivity requirements—particularly for critical applications like power transmission lines.

Regardless of the specific alloy series, two fundamental challenges persist in every aluminum melt: removing dissolved hydrogen and effectively controlling dross formation. Mastering these core tasks, alongside the specific strategies for each alloy family, is the true art of producing high-quality molten aluminum.

Why Aluminum Alloy Melting Truly Matters

Think of melting as the crucial foundation for everything that follows in aluminum processing. The process goes beyond simply liquefying solid metal.

Precise chemical composition achieved during melting is fundamental. It directly ensures the final alloy delivers its designed strength, corrosion resistance, conductivity, or other vital properties.

Furthermore, melt quality—specifically cleanliness and low gas levels—dictates the product’s internal integrity. Minimizing dissolved hydrogen gas and removing solid impurities is essential. This directly prevents defects like porosity, weak spots, or poor surface finish. This improves durability, resistance to stress, long-term performance, and general dependability.

Melting also unlocks aluminum’s superpower: sustainability. Recycling aluminum scrap saves massive energy—about 95% less than making new metal! But turning scrap into high-performance material depends entirely on advanced melting and purification techniques.

Good melting isn’t just about quality; it’s smart economics too. Optimized processes reduce metal loss, improve yield, lower scrap rates, and boost overall efficiency.

In short, successful melting is where material science meets precise control. This is the essential step. It transforms raw materials into clean, uniform melt. The process handles both fresh ingots and recycled scrap. The output is high-quality liquid metal ready for precise shaping. Getting this process right guarantees the end product performs flawlessly under extreme conditions.

Conclusion

This journey through aluminum alloy melting reveals the unsung hero behind every lightweight frame, sleek gadget, and fuel-efficient vehicle. We’ve mapped the diverse alloy families and decoded the science of purification. Along the way, we’ve tackled challenges—whether taming magnesium’s oxidation in 5xxx alloys or mastering silicon modification in castings.

Crucially, we’ve seen how molten precision dictates performance: a flawless melt means resilience against cracks, corrosion, and fatigue. It also unlocks aluminum’s green superpower—recycling scrap at 5% of virgin metal’s energy cost.

So, next time you hold an aluminum product, imagine its fiery rebirth: engineers balancing heat, chemistry, and timing to transform glowing liquid into reliable strength. Behind that “effortless” lightness lies calculated mastery.

This is where material futures are forged. Advancements in melting won’t just refine alloys—they’ll accelerate innovations in sustainable transport, energy efficiency, and beyond. Because when we perfect the art of the melt, we shape a future that’s lighter, stronger, and kinder to our planet.