Vacuum induction furnace maintenance is critical for modern precious metal processing, particularly in high-purity gold production, where oxidation and contamination must be strictly controlled.

Gold melting requires strict environmental control. The vacuum induction melting process creates an oxygen-free space, which is critical for achieving 99.99%+ purity. Additionally, precise alloying becomes possible, making VIM furnaces ideal for specialized gold applications like aerospace solders and high-end jewelry.

However, maintaining these furnaces demands special attention. Regular checks on seals, crucibles, and cooling systems are necessary to prevent defects.

This blog provides practical maintenance strategies to help operators optimize their VIM furnace performance for gold melting, ensuring both superior metal quality and cost-effective operations.

By following these best practices, users can extend equipment lifespan while minimizing costly downtime and purity issues.

When to Use Vacuum Induction Melting Furnaces

Vacuum induction melting (VIM) furnaces are the preferred choice for gold processing when exceptional purity and controlled conditions are required. These advanced systems provide distinct benefits, making them essential for critical industrial applications.

High-Purity Gold Production

First and foremost, VIM furnaces are unmatched in producing gold with purity levels of 99.99% or higher. This level of purity is essential for LBMA-standard gold ingots and premium bullion coins like the Canadian Maple Leaf 9999.

Since gold is highly susceptible to oxidation and contamination, the vacuum environment ensures that no unwanted elements compromise the metal’s quality.

Moreover, the induction heating method allows for precise temperature control, which is critical for maintaining consistency in high-value gold products.

Oxidation-Sensitive Alloys

Another major application is melting oxidation-sensitive gold alloys, such as Au-Ir and Au-Pt. These alloys are often used in specialized industrial and jewelry applications where even trace oxygen exposure can degrade performance.

The vacuum-sealed chamber of a VIM furnace eliminates this risk, ensuring that the final product retains its desired properties. Additionally, the induction process minimizes material loss, making it cost-effective for high-value alloys.

Specialized Gold-Based Solders

Furthermore, VIM furnaces are widely used in aerospace and electronics manufacturing for producing gold-based solders like Au-Ge and Au-Si. These solders require impurity-free conditions to ensure strong, reliable bonds in critical components.

The vacuum chamber eliminates gas and particle contamination, while electromagnetic induction ensures consistent alloy blending. As a result, manufacturers can achieve consistent solder quality, which is vital for high-performance applications.

High-Value Scrap Recovery

Vacuum induction melting furnaces have become indispensable for recovering gold from high-value scrap materials, especially electronic waste. The vacuum environment plays a dual role—it eliminates oxygen to prevent oxidation while simultaneously vaporizing organic contaminants that often coat recycled gold components.

This purification process typically achieves recovery rates exceeding 99.5%, significantly higher than conventional smelting methods.

For recyclers, the economic benefits are substantial. By extracting nearly all available gold content, VIM systems turn what would be waste into profitable material. Environmentally, the closed-loop system prevents toxic emissions associated with traditional refining.

The process works equally well for jewelry scrap, dental gold, and industrial byproducts, making VIM technology a versatile solution for sustainable precious metal recovery.

VIM Furnaces Industry Application

Leading precious metal refiners depend on VIM furnaces to consistently produce investment-grade gold meeting LBMA’s stringent 99.99% purity standards.

Research institutions and jewelry manufacturers also utilize this technology for developing specialized gold alloys and platinum-gold compositions that require oxygen-free processing environments.

The system’s versatility accommodates operations of all scales, from industrial refineries processing bulk materials to boutique workshops handling specialty projects.

This broad industry adoption highlights VIM’s unique capability for contamination-free melting. Its repeatable precision makes it the preferred choice for applications demanding absolute purity and consistency.

Understanding these applications highlights why VIM furnaces are so effective for gold melting. However, their performance depends on several critical components, including the vacuum system, induction coil, and crucible design.

In the next section, we will examine these essential elements and how they contribute to optimal furnace operation.

Key Components of a VIM Furnace

A vacuum induction melting (VIM) furnace for gold processing comprises several sophisticated subsystems that work in harmony to achieve contamination-free melting. Each component plays a vital role in maintaining the purity and quality of molten gold while ensuring operational efficiency and safety.

1. Vacuum System

The heart of the VIM furnace is its vacuum system, which creates the essential oxygen-free environment. This system consists of:

- Mechanical pumps: Generate the initial vacuum level, reaching pressures as low as 10⁻³ mbar

- Diffusion pumps: Attain ultra-high vacuum conditions, achieving pressures below 10⁻⁵ mbar

- Vacuum valves and gauges: Enable precise pressure regulation and accurate real-time monitoring

- Sealing mechanisms: Use special fluoropolymer materials to prevent leaks

For gold melting, oil-free vacuum pumps are mandatory to eliminate hydrocarbon contamination. The system must maintain a stable vacuum throughout the melting cycle to prevent gold oxidation and ensure proper degassing.

2. Induction Heating System

The electromagnetic induction system provides controlled heating through:

- High-frequency power supply: Typically operates at 3-10 kHz for gold

- Water-cooled copper coil: Precisely wound for optimal electromagnetic coupling

- Impedance matching network: Ensures efficient power transfer

- Cooling system: Maintains coil temperature with deionized water

Gold’s high electrical conductivity requires careful coil design to achieve uniform heating while minimizing energy consumption. The system must compensate for gold’s tendency to develop skin effects at high frequencies.

3. Crucible Assembly

The crucible serves as the containment vessel and must meet strict requirements:

- Material selection: High-purity options such as graphite, zirconia (ZrO₂), or cubic boron nitride (c-BN) are available for optimal performance

- Thermal properties: Must withstand rapid temperature changes

- Chemical resistance: Should prevent gold penetration and reaction

- Design features: Includes proper wall thickness and base support

Boron nitride-coated graphite crucibles offer excellent performance for gold, combining good thermal conductivity with superior chemical resistance. The crucible’s dimensions must match the induction coil for efficient energy transfer.

4. Temperature Monitoring and Control

Precise temperature regulation is achieved through:

- Infrared pyrometers: Provide non-contact temperature measurement

- Thermocouples: Offer backup temperature monitoring

- PLC-based control system: Maintains ±2°C stability

- Safety systems: Prevent overheating and thermal runaway

The control system must account for gold’s relatively low melting point (1064°C) and high thermal conductivity to prevent localized overheating.

5. Auxiliary Systems

Additional supporting components include:

- Gas handling system: For inert gas introduction when needed

- Viewing ports: Enable visual process monitoring

- Tilting mechanism: Facilitates controlled pouring

- Dust collection: Captures gold vapor condensate

Each auxiliary system must use gold-compatible materials to prevent contamination. The gas system, for example, should use ultra-high purity argon with oxygen levels below 5 ppm.

6. Safety and Monitoring Features

Modern VIM furnaces incorporate multiple safety systems:

- Leak detection sensors: Monitor vacuum integrity

- Water flow sensors: Ensure proper cooling

- Pressure relief valves: Prevent over-pressurization

- Emergency shutdown: Activated by critical parameter deviations

These features are particularly important for gold processing, where even minor contamination can significantly impact product quality.

Understanding these components is just the first step in operating a VIM furnace effectively. To maintain peak performance and ensure consistent gold quality, each component requires specific maintenance attention.

The next section will detail the essential routine maintenance procedures that keep your VIM furnace operating at its best, from daily inspections to comprehensive quarterly maintenance protocols.

Routine Maintenance of Vacuum Induction Furnaces

Maintaining your vacuum induction melting furnace for gold processing requires strict, well-organized routines.

Gold’s unique properties demand special attention to prevent contamination, ensure vacuum integrity, and protect critical components. Let’s break down the essential procedures before, during, and after each melting cycle.

Pre-Melting Checks

Before beginning any gold melt, thorough preparation is non-negotiable. First and foremost, perform a comprehensive vacuum leak test. This step is critical because even tiny leaks introduce oxygen or contaminants, ruining the oxidation-free environment needed for high-purity gold.

For optimal sensitivity, employ a helium mass spectrometer in leak detection. Your target vacuum level should be consistently better than 10⁻³ mbar, specifically for gold melting, to prevent any atmospheric interaction.

Simultaneously, inspect all seals meticulously. Replace any O-rings showing signs of aging, cracking, or flattening immediately. Fluorocarbon rubber O-rings are highly recommended for gold applications, as they resist high temperatures better and avoid the contamination risks associated with greased seals.

Next, turn your attention to the crucible. This component holds your molten gold, making its condition paramount. Begin by removing all residues from previous melts. Even minuscule traces of a different alloy or lower purity gold can contaminate your next batch, compromising purity specifications like the LBMA’s 99.99% standard.

Use appropriate, non-abrasive cleaning tools and methods approved for your crucible material. Following cleaning, conduct a detailed visual and tactile inspection. Look closely for hairline cracks, significant erosion, or thinning spots.

Remember, molten gold is extremely dense. This high density significantly accelerates wear on crucible walls compared to melting less dense metals. Never use a crucible showing any signs of compromise; the risk of failure during a melt is too severe.

During-Melting Monitoring

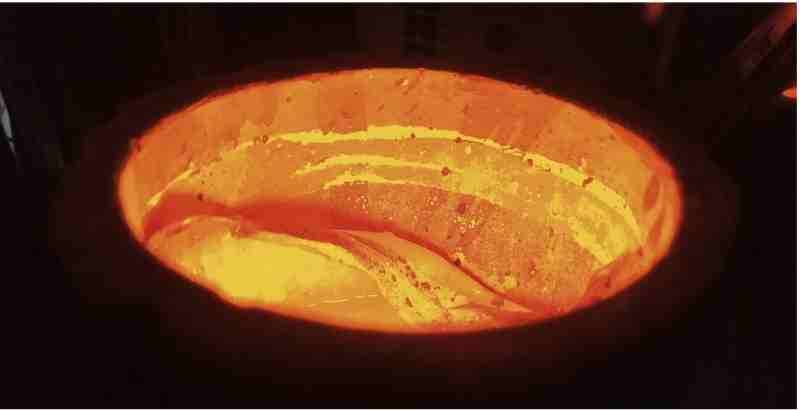

Once the melting process commences, continuous monitoring becomes your primary task.

The cooling system demands constant attention. Gold melts at 1064°C (1947°F), and the induction coil generates intense heat. Consequently, closely monitor both the flow rate and temperature of the cooling water circulating through the coil and other components.

Any significant drop in flow rate or a rise in outlet water temperature signals potential overheating, which can damage the coil insulation or even cause coil failure.

Furthermore, prevent scaling within the cooling channels by exclusively using deionized water. Tap water contains minerals like calcium and magnesium; these leave deposits that insulate heat transfer surfaces and drastically reduce cooling efficiency over time.

Simultaneously, maintaining vacuum integrity during the melt is essential. Continuously observe the vacuum gauge readings. A sudden or gradual pressure rise indicates a problem.

Potential causes include seal failure, a valve malfunction, or, crucially for gold, the accumulation of vaporized gold within the pump system. At its melting point and in the immediate temperature range above it, gold exhibits considerable vapor pressure.

These vapors can travel back into the vacuum system, potentially condensing and clogging pump filters or contaminating vacuum oil. Any abnormal pressure fluctuations require instantaneous diagnostic evaluation.

Post-Melting Maintenance

After the gold has solidified and the furnace has cooled sufficiently, post-melt cleanup and inspection begin.

Crucible residue removal:

It is your first critical step. Molten gold readily wets many surfaces, leaving behind tiny adhered particles. To recover this valuable material and prevent cross-contamination in future melts, use dedicated, non-contaminating tools.

Quartz rods are excellent for carefully scraping residues from crucible walls without scratching the surface or introducing impurities. Crucially, meticulously clean the furnace chamber floor and other surfaces where conductive gold dust might settle.

Gold dust is highly conductive; accumulations pose a serious risk of electrical short circuits within the furnace chamber, potentially damaging the power supply or control systems.

Use appropriate vacuum cleaners with HEPA filters designed for metal dust and lint-free wipes dampened with high-purity alcohol.

Learn about what HEPA filters are.

Induction coil and power supply:

Following cleanup, shift focus to the induction coil and power supply. The high electrical conductivity of molten gold creates a strong electromagnetic coupling with the coil. This intense interaction can sometimes cause localized stress or uneven heating.

Therefore, measure the coil’s impedance after the furnace has cooled completely. Compare this reading to baseline values established when the coil was new or after professional servicing.

Significant variations in impedance can indicate developing issues like insulation breakdown, subtle physical distortion, or uneven cooling channel blockage. Early detection through this simple measurement allows for proactive maintenance before a major failure occurs.

Visual inspection:

Finally, perform a general visual inspection of all accessible components, looking for any signs of splatter, unusual wear, or damage incurred during the melting cycle. Document all findings and actions taken for your maintenance records.

Diligently following this structured routine safeguards the purity of your gold melts. It also protects your valuable furnace investment. Finally, it ensures consistent, reliable performance cycle after cycle.

This routine includes rigorous pre-checks, attentive monitoring during operation, and thorough post-melt procedures. This disciplined approach is fundamental to successful high-purity gold production using VIM technology.

Long-Term Maintenance Strategies

Building on the essential daily routines, effective long-term maintenance of your gold VIM furnace requires strategic planning.

Consistent preventive care and smart spare parts management prevent costly breakdowns and safeguard gold purity over thousands of operating hours. We will now examine systematic maintenance protocols designed to maximize furnace operational longevity.

Preventive Maintenance Schedule

Implementing a strict preventive schedule is non-negotiable for gold processing. Monthly tasks demand focused attention. First, conduct full-system leak detection using helium mass spectrometers.

Gold’s sensitivity to oxygen makes this critical—even minor leaks below 10⁻³ mbar can introduce contaminants. Next, replace vacuum pump oil. Unlike other metals, gold vapors rapidly degrade standard oils. Use only high-boiling-point, gold-compatible fluids to avoid pump corrosion and costly rebuilds.

Quarterly interventions address high-wear components. Perform detailed coil insulation resistance tests. Molten gold’s extreme conductivity stresses coil insulation over time; identify early degradation before arcing occurs.

Simultaneously, replace crucibles proactively. Even crucibles lacking visible defects experience gold-induced nanoscale wear that degrades melt purity through cumulative material loss. Rotate ceramic or BN-coated units quarterly to prevent catastrophic failures.

Spare Parts Management

Stocking the right spare parts avoids production halts and contamination risks. Prioritize gold-critical components in your inventory:

- Ceramic Crucibles: Keep at least two furnace-specific spares. Gold’s wetting behavior varies by crucible composition; mismatched materials cause gold loss.

- Sulfur-Free Seals: Store FKM/Viton® O-rings in climate-controlled packaging. Standard seals release sulfur that embrittles gold.

- Vapor Traps: Maintain backup condensers. Gold volatilization clogs standard traps faster than other metals.

Develop a consumption tracking system. Log crucible usage cycles and seal replacement dates. For example, note if pump oil darkens faster with high-volatility gold alloys. This data predicts future needs and spots abnormal wear patterns.

Critical Longevity Extenders

Three often-overlooked strategies significantly impact ROI:

- Coil Water Quality Monitoring: Test cooling water monthly for resistivity (>1 MΩ·cm). Mineral buildup from poor water accelerates coil corrosion—a leading cause of power supply failures.

- Tool Calibration Cycles: Recalibrate pyrometers quarterly. Gold’s precise melting point (1064°C) requires ±2°C accuracy; drift causes overheating and crucible damage.

Begin by auditing your current schedule against these benchmarks. If quarterly coil checks aren’t documented, initiate them immediately.

Next, review spare parts: Replace any standard seals with gold-rated versions. Finally, coordinate with manufacturers for furnace-specific training. Valcambi’s technicians.

By investing in scheduled care and specialized spares, you ensure decade-long reliability while meeting LBMA 99.99% purity standards batch after batch. Remember: In gold melting, prevention isn’t just cheaper than repairs—it’s the guardian of your product’ s integrity.

Special Considerations for Gold Melting

While long-term maintenance strategies form the backbone of furnace care, gold’s unique properties demand additional specialized attention. Unlike other metals, gold processing presents distinct challenges that require tailored solutions.

Let’s examine the critical areas where standard procedures won’t suffice when working with this precious metal.

Contamination Control of Gold Melting

Gold’s purity is its most valuable characteristic, making contamination prevention absolutely essential. First and foremost, implement a strict tool policy. Ban all iron-containing tools from your workspace completely.

Even trace amounts of iron can introduce impurities that compromise gold’s conductivity and color. Instead, use only titanium, quartz, or ceramic tools specifically designed for gold handling.

Next, develop meticulous chamber cleaning protocols. Standard cleaning methods often leave behind invisible contaminants. Always use high-purity isopropyl alcohol with lint-free wipes for all interior surfaces.

Regular paper towels or cloth rags shed fibers that can become embedded in molten gold. For best results, clean the chamber immediately after cooling but before opening to atmospheric pressure, as this prevents airborne particles from settling on surfaces.

Vapor Management

Gold’s tendency to vaporize at high temperatures presents unique challenges that many operators overlook. Unlike base metals, gold generates significant vapor pressure even at standard melting temperatures. This means you must take extra precautions with your vacuum system.

First, establish a rigorous pump oil maintenance schedule. Gold vapors condense in pump oil, forming sludge that drastically reduces performance.

Change oil twice as frequently as recommended for standard metals, and always use high-temperature formulations. Better yet, consider switching to dry pump systems, which eliminate oil contamination entirely.

Second, install specialized gold vapor traps in your vacuum line. These should be checked and cleaned monthly, or more often for high-volume operations. Look for traps specifically designed for precious metals, as they feature finer filtration to capture microscopic gold particles.

Crucible Selection for VIM Furnaces

Your choice of crucible material makes all the difference in gold melting. Standard graphite or clay-graphite crucibles simply won’t deliver the results you need. Boron nitride (BN)-coated crucibles have become the industry standard for good reason.

The BN coating creates a non-wetting surface that prevents gold penetration into the crucible walls. This not only reduces material loss but also minimizes contamination between batches.

When selecting crucibles, look for those with at least 95% BN content in the coating. Lower quality coatings may contain binders that react with molten gold.

Remember to condition new crucibles properly before use. Heat them gradually to 200°C above your working temperature to stabilize the coating. This simple step can extend crucible life by up to 30%.

Maintain detailed logs for each melt, including crucible history, vacuum levels, and any deviations from standard procedures. This documentation proves invaluable for troubleshooting and quality assurance.

By implementing these specialized practices, you’ll protect your gold’s value while maximizing furnace performance. Please remember, in gold processing, the extra attention to detail always pays dividends in product quality and operational efficiency.

These considerations aren’t just best practices—they’re essential requirements for anyone serious about gold melting at the highest levels of purity.

Troubleshooting Common Issues in Gold Melting

Even with proper maintenance, gold melting operations can encounter specific challenges. Let’ s examine two critical issues and their solutions to minimize downtime and protect gold purity.

Rapid Vacuum Loss

First, check the seals if you notice sudden pressure increases. Gold processing accelerates seal degradation because vapors penetrate and harden rubber over time. Look for flattened or cracked O-rings, especially around viewports and feedthroughs.

Next, inspect the vacuum oil. Gold vapors condense in standard oils, forming sludge that reduces pumping efficiency. If the oil appears dark or metallic, replace it immediately with high-temperature oil rated for precious metals.

For quick resolution:

- Replace all seals every 3 months (or after 50 melts)

- Install gold-rated seals (FKM/Viton® with sulfur-free additives)

- Upgrade to dry pumps if oil contamination recurs

Unstable Melt Temperature

Start by verifying thermocouple calibration. Gold’s melting point requires exacting temperature control—deviations exceeding 10°C can significantly degrade product quality. Use a secondary pyrometer to cross-check readings.

Then, examine the induction coil. Gold’s high conductivity creates uneven electromagnetic loads, which may overheat coil sections. Look for discolored or warped turns indicating cooling problems.

Key corrective actions:

- Recalibrate sensors monthly with gold reference standards

- Flush cooling channels to remove mineral deposits

- Measure coil impedance weekly to detect early insulation wear

Log each incident’s symptoms and solutions. This helps spot patterns—for example, if temperature instability always occurs after crucible changes, alignment may be the root cause.

By addressing these issues promptly, you’ll maintain both furnace performance and gold purity standards. For persistent problems, consult your furnace manufacturer—many offer gold-specific troubleshooting guides.

Conclusion

Proper maintenance of vacuum induction melting (VIM) furnaces is crucial for achieving high-purity gold production, as these specialized systems require meticulous care of seals, crucibles, and cooling systems to prevent contamination and ensure optimal performance.

While vacuum induction melting furnaces remain the gold standard for achieving ultra-high purity in gold processing, conventional induction melting furnaces can serve as a cost-effective alternative for certain gold melting applications.

For businesses seeking reliable and cost-effective induction melting solutions, explore FOCO Induction‘s advanced furnaces.