Induction melting technology improves molten steel purity like no other method. But why does purity matter so much? Think about aerospace turbines or surgical tools—tiny impurities can cause big failures. That’s where induction melting shines.

First, let’s talk steel quality. Clean steel means fewer inclusions, lower gas content (H/O/N), and precise control of trace elements. High-purity steel isn’t just nice to have—it’s a must for critical applications like jet engines or nuclear reactors.

Now, here’s the cool part: induction melting beats traditional furnaces. No electrode carburization, no messy contamination. Instead, electromagnetic stirring pushes impurities out naturally. No wonder it’s the go-to for premium special steel.

In this post, we’ll break down how induction melting works its magic—plus practical tips to optimize your process. Ready to dive in? Let’s go.

Why Steel Melt Purity Matters

Steel purity isn’t just a technical detail—it’s the difference between a high-performance alloy and a ticking time bomb. Whether it’s strength, durability, or cost efficiency, impurities like sulfur, oxygen, or trace metals can ruin everything.

Let’s break down why clean steel matters across four key areas: quality, high-end applications, production costs, and industry competition.

Affecting Steel Quality

First, mechanical properties take a hit when impurities sneak in. Sulfur and phosphorus weaken steel, making it brittle under stress. Oxygen? Even worse.

Tiny oxide inclusions act like micro-cracks, killing fatigue life and toughness. Imagine a bridge or a gearbox failing because of invisible flaws—scary, right?

Then there’s corrosion. Non-metallic junk like Al₂O₃ disrupts steel’s structure, creating weak spots where rust attacks faster. And if you’re rolling or forging the steel, sulfur and phosphorus can trigger hot or cold brittleness, turning your smooth process into a crack-filled nightmare.

Requirements for High-End Applications

Now, let’s talk about the big leagues—aerospace, medical, and EVs. Turbine blades and nuclear components demand oxygen levels below 10 ppm; any higher, and you risk catastrophic failure. Medical implants? Even tiny inclusions can trigger immune reactions or wear down prematurely.

Electric vehicles add another challenge: hydrogen embrittlement. High-strength steel loves to absorb hydrogen, which turns it brittle over time. That’s why automakers obsess over ultra-low hydrogen steel—because nobody wants a car frame cracking under pressure.

Steel Production Costs

Dirty steel isn’t just weak—it’s expensive. Low-purity melts lead to pores, shrinkage cavities, and rejects, driving up scrap rates. Worse, impurities like lead or tin can wreck continuous casting, causing cracks that halt production.

Then there’s regulation. ISO and other standards keep tightening limits on toxic elements (cadmium, mercury, etc.). Fail to comply, and you’re stuck with fines or costly process overhauls. Clean steel isn’t just better—it’s cheaper in the long run.

Industry Competition

Finally, the market doesn’t wait. Giants like Nippon Steel dominate with ultra-low oxygen (ULO) tech, while automakers (Toyota, Tesla) audit suppliers based on purity specs. If your steel isn’t clean, you’re locked out of the premium market.

Bottom line? Purity isn’t optional—it’s survival. Whether you’re fighting defects, meeting specs, or staying competitive, cleaner steel means stronger products and smoother profits. Next, we’ll dive into how induction melting solves these problems—stay tuned!

How to Improve Molten Steel Purity Using Induction Melting Technology

Steel purity isn’t just about removing junk—it’s about how you remove it. Traditional furnaces struggle with uneven mixing, contamination, and sluggish refining. But induction melting? It’s like giving steel a high-tech detox.

Let’s explore the key ways induction technology delivers cleaner, higher-quality steel—from electromagnetic stirring to precision temperature control, smart deoxidation, and beyond.

Electromagnetic Stirring

Precise control of chemical composition during melting, especially achieving high uniformity, directly determines the final performance and quality of steel.

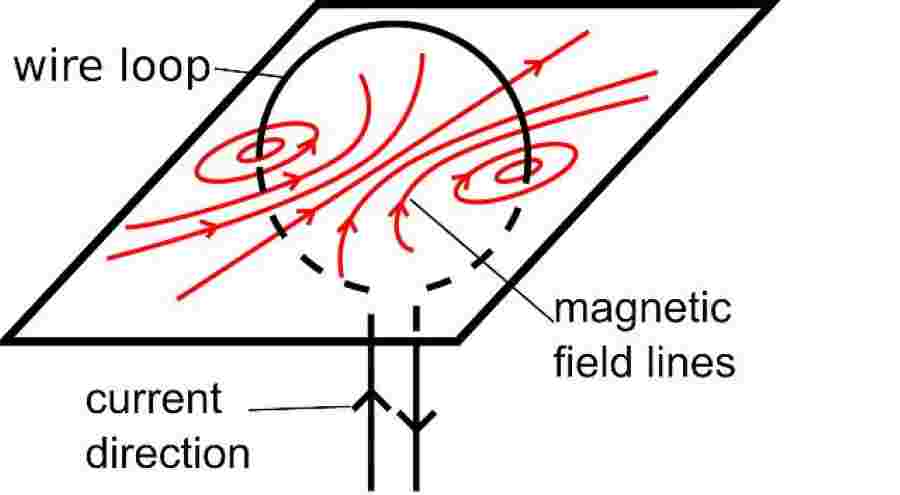

Induction melting offers a key advantage. Its powerful electromagnetic stirring acts without contact. This force mixes the liquid steel rapidly and completely. This technology achieves unprecedented thermal and chemical uniformity via intense forced convection.

Electromagnetic stirring also minimizes both macro- and microsegregation throughout the entire batch. This ensures highly consistent steel chemistry. Compared to traditional arc furnaces, induction stirring is more effective. Arc furnaces rely on mechanical or gas injection. Induction is also cleaner, avoiding secondary pollution.

What’s more, modern induction furnaces typically use integrated online spectral analyzers. These systems give precise chemistry results in just minutes. Plants combine this rapid analysis with closed-loop control systems. Operators, or the system itself, can then make immediate corrections.

It adds precise amounts of alloying elements. This capability enables fine trimming of the final composition. Consequently, it dramatically increases target accuracy. Batch-to-batch consistency also improves significantly.

Learn more about electromagnetic stirring.

Temperature Control

Achieving optimal temperature control is fundamental to producing high-quality steel.

Superheat temperature: it activates essential metallurgical reactions, including deoxidation, desulfurization, and degassing, while simultaneously promoting the aggregation and flotation of non-metallic inclusions.

However, this parameter requires careful balancing. Insufficient heat fails to complete these purification processes, while excessive temperatures lead to increased energy consumption, accelerated refractory wear, and undesirable metal loss through oxidation and evaporation.

Holding time: Equally important is the holding time at target temperatures. This duration must be precisely calculated to allow sufficient time for reaction products and inclusions to separate effectively.

Too brief a holding period results in incomplete purification, leaving harmful elements in the melt. Conversely, prolonged holding increases the risk of gas absorption from the atmosphere while unnecessarily extending production cycles and raising energy costs.

Modern induction furnace technology provides distinct advantages in thermal management:

- Rapid, efficient heating through direct electromagnetic energy transfer to the metal charge.

- Precise temperature zoning capability that maintains optimal thermal gradients.

- Advanced thermal insulation systems effectively reduce energy dissipation to surrounding areas.

- Reduced oxidation due to lower ambient furnace temperatures.

The combination of optimized temperature parameters with advanced induction heating technology creates ideal conditions for producing cleaner, more homogeneous steel with superior mechanical properties.

Deoxidation and Degassing

Non-metallic inclusions and dissolved gases constitute the most destructive impurities in steel. Oxide particles initiate fatigue cracks, while hydrogen induces delayed brittle fracture. Precise deoxidation and degassing directly determine:

- Fatigue life (>70% extension with clean steel)

- Fracture toughness (H₂ < 2 ppm prevents hydrogen embrittlement)

- Corrosion resistance (Cr/Fe oxides accelerate pitting)

Deoxidizer Selection

Common deoxidizers include aluminum (Al), silicon-manganese (Si-Mn), and calcium-silicon (Ca-Si).

Precipitation deoxidation directly adds deoxidizers (e.g., Al blocks, Si-Mn blocks) into molten steel, forming oxide inclusions that float up.

Diffusion deoxidation introduces deoxidizers (e.g., C powder, Si powder, Al powder) into slag to reduce FeO content, promoting oxygen transfer from steel to slag—often combined with precipitation deoxidation.

Complex deoxidation/calcium treatment modifies solid deoxidation products (e.g., Al₂O₃) into low-melting-point calcium aluminates via Ca-Si addition, enhancing castability and improving purity.

Discover more knowledge about deoxidizer selection.

Vacuum/Inert Gas Protection

Vacuum degassing (VD, VOD) removes dissolved gases under low pressure via partial pressure principles while boosting carbon-oxygen reactions—critical for ultra-low-gas steels (e.g., bearing/rotor steels).

Inert gas shielding (Ar, N₂) covers molten steel during smelting/pouring via surface purging or bottom stirring, preventing reoxidation and gas absorption, ideal for high-oxidation-sensitivity alloys.

Induction Furnace Advantages

Superior sealing (especially medium-frequency coreless/vacuum induction furnaces) enables easy maintenance of reducing/inert/vacuum atmospheres.

Electromagnetic stirring accelerates inclusion/bubble collision, growth, and removal, cutting purification time by 30–50% versus conventional methods.

Lining Material and Refractoriness

The choice of furnace lining materials plays a decisive role in steel quality. Whether using basic magnesia, neutral alumina, or acidic silica linings, the selection must precisely match the steel grade being produced.

An incompatible lining can introduce harmful elements into the melt. Acidic refractory materials can lead to silicon pickup in low-carbon grades, whereas basic linings are a prerequisite for clean alloy steel manufacturing. Beyond chemical compatibility, the lining’s properties directly influence slag chemistry, affecting critical refining reactions like phosphorus and sulfur removal.

Furnace linings face constant attack from multiple fronts. The intense heat of molten steel, combined with chemical reactions from slag components and mechanical stresses from electromagnetic stirring, gradually wears down the refractory material.

This erosion doesn’t just shorten lining life; it releases particles into the steel that become dangerous exogenous inclusions. Studies show these lining-derived contaminants can account for nearly one-third of total impurities in some production scenarios.

Modern induction furnaces combat these challenges with advanced lining technologies. High-purity materials like fused magnesia and spinel-bonded refractories now offer superior resistance to both thermal and chemical attacks.

These engineered solutions demonstrate remarkable performance—typically doubling service life while cutting erosion rates by half compared to conventional linings. Perhaps most importantly, they reduce inclusion counts by 50-80%, directly contributing to cleaner steel production.

Dry-rammed and precast lining systems have further improved installation consistency, ensuring more reliable protection against contamination.

Melting Operation Specifications

The production of high-quality steel demands rigorous adherence to standardized operating procedures.

A carefully designed charging sequence forms the foundation of successful melting—refractory alloys and dense materials must be introduced first, followed by lighter, more oxidation-prone elements.

Maintaining optimal melting rates prevents localized overheating while ensuring efficient energy use.

Effective slag control requires maintaining specific chemical formulations and optimal viscosity ranges throughout the operation. This protective layer serves dual purposes: shielding the molten steel from atmospheric contamination while actively absorbing undesirable inclusions. Continuous monitoring ensures the slag performs these functions effectively throughout the operation.

Modern induction furnace technology significantly enhances operational control. The inherent electromagnetic stirring provides automatic and uniform mixing, promoting both temperature homogeneity and inclusion removal.

Advanced automation systems take this precision further by maintaining exact power levels and temperature profiles consistently throughout each batch.

The cumulative effect of these controlled parameters determines the final product quality. Optimal stirring intensity, carefully monitored holding times, and exact temperature maintenance work together to produce steel with superior purity and consistency.

Induction technology’s rapid heating capabilities and clean operation further contribute to this quality while improving energy efficiency.

Steel Melting Process Optimization Strategies

Getting high-purity steel isn’t just about having the right furnace—it’s about how you run it. From the moment you load raw materials to the final pour, every step affects quality. Let’s break down the pre-melting prep, refining tricks, and post-treatment moves that turn good steel into great steel.

Pre-Melting Preparation

- Charge Material Selection—No Junk Allowed

Garbage in, garbage out—this is especially true for steelmaking. To avoid contamination:

- Use classified scrap—no painted, oily, or mixed metals that add sulfur, phosphorus, or other nasties.

- Pre-dry alloys—wet materials cause hydrogen pickup (and explosions, in extreme cases).

- Control size (20-50 mm chunks)—too big slows melting; too fine burns off before dissolving.

Pro tip: If you’re smelting high-grade alloys, consider pre-melted stock to skip impurity risks altogether.

- Lining Inspection—Don’t Let Your Furnace Poison the Steel

A cracked or poorly preheated lining is a recipe for disaster. Here’s how to do it right:

- Check for cracks—small ones can be patched; big ones mean relining.

- Preheat slowly—thermal shock causes spalling (and flakes in your molten steel).

Room temp → 200°C (2 hrs): Drives out moisture.

200°C → 800°C (3 hrs): Gentle ramp-up avoids cracks.

800°C → working temp (1 hr): Even heat for stable operation.

Why bother? A bad lining leaches silicon, carbon, or alumina into your melt—ruining chemistry before you even start.

Steel Melting & Refining

Getting the melting and refining stages right is where good steel becomes great steel. Induction furnaces give you surgical control—if you know how to use it. Here’s how to optimize each phase for maximum purity:

- Power Control—Three Stages to Perfection

Induction furnaces thrive on smart power management, and the key is breaking the process into three deliberate stages:

Stage 1: Rapid Melting (0-15 min, 100% power)

Crank the power to full blast. The goal? Melt fast to minimize oxidation and gas pickup. Slow melting lets oxygen and nitrogen creep in, so speed is your friend here.

Stage 2: Refining (15-25 min, 60% power + 3-5Hz stirring)

Now, ease off the heat but ramp up stirring. The electromagnetic agitation forces inclusions to collide, merge, and float into the slag. Adjust stirring based on slag thickness—thicker slag needs more agitation (5 Hz+) to push impurities out.

Stage 3: Holding (25-35 min, 30% power)

Finally, maintain a gentle boil to let the last impurities rise. Too much heat here wastes energy; too little leaves junk in the melt.

Pro tip: Watch the slag. If it’s too viscous, tweak stirring to keep inclusions moving.

- Holding Treatment—Where Impurities Get Evicted

Not all steels are created equal—each grade needs a tailored hold:

- Bearing steel (1580°C, 35 min, 5 Hz stirring)

Demands the longest hold for ≤10 µm inclusions. The high temp and aggressive stirring ensure even the tiniest flaws float out.

- Stainless steel (1550°C, 25 min, 3 Hz stirring)

A balance act—remove inclusions without losing too much chromium to oxidation.

- Electrical steel (1520°C, 20min, 1Hz stirring)

Gentle treatment prevents grain distortion, which kills magnetic performance.

Watch for: Over-stirring can drag floated inclusions back down. Sometimes, a calmer melt is a cleaner melt.

Post-Melting Treatment: Locking in Purity

- Argon Refining – The Final Gas Flush

Before casting, give the steel an argon shower:

Blow argon through porous plugs—tiny bubbles grab [H] and [O] on their way up.

Stop when gas specs hit the target—usually <2ppm [H], <15ppm [O] for most alloys.

Bonus: Argon also helps homogenize temperature—critical for smooth casting.

- Continuous Casting—Don’t Ruin Good Steel at the Last Step

Even perfect molten steel can get wrecked during pouring. Avoid disasters with:

- Tundish flux—basic cover (CaO-Al₂O₃) prevents reoxidation.

- Argon-shrouded pouring seals liquid steel from air.

- Dynamic cooling—thicker slabs need heavier secondary cooling to avoid cracks.

Troubleshooting quick fixes:

Nozzle clogged? Switch to backup ASAP—stopping mid-cast ruins microstructure.

Slag sneaking in? Reduce casting speed and boost argon flow to push it back.

Optimizing steel purity isn’t about one big trick—it’s about nailing a hundred small details. From picking clean scrap to fine-tuning argon flow, every step stacks up. Master these strategies, and you’ll turn batch-to-batch guesswork into repeatable, high-purity results

Conclusion

From aerospace turbines to medical implants, molten steel purity makes or breaks performance. Induction melting delivers what traditional methods can’t—faster deoxidation, pinpoint temperature control, and electromagnetic stirring that kicks impurities to the curb.

Whether you’re battling inclusions, hydrogen pickup, or inconsistent chemistry, induction technology offers cleaner steel, lower costs, and repeatable quality.

Ready to upgrade your melting process? FOCO Induction’s advanced melting furnaces combine precision power control, automated stirring, and high-purity linings—helping you produce ultra-clean steel, batch after batch.