Metal combinations for induction brazing aren’t just a technical detail—they’re the secret sauce for strong, lasting joints. Consider this: Your metal combinations dictate performance. In lightweight cars, heavy-duty tools, or precision electronics, the right pairing ensures optimal strength, corrosion resistance, and stress handling.

Here’s the thing: mixing different metals brings challenges. Think aluminum and steel. Two major challenges arise: First, their thermal expansion rates differ drastically when heated. Second, aluminum forms a stubborn oxide layer. Both can create weak spots or brittle joints. That’s the headache induction brazing often solves.

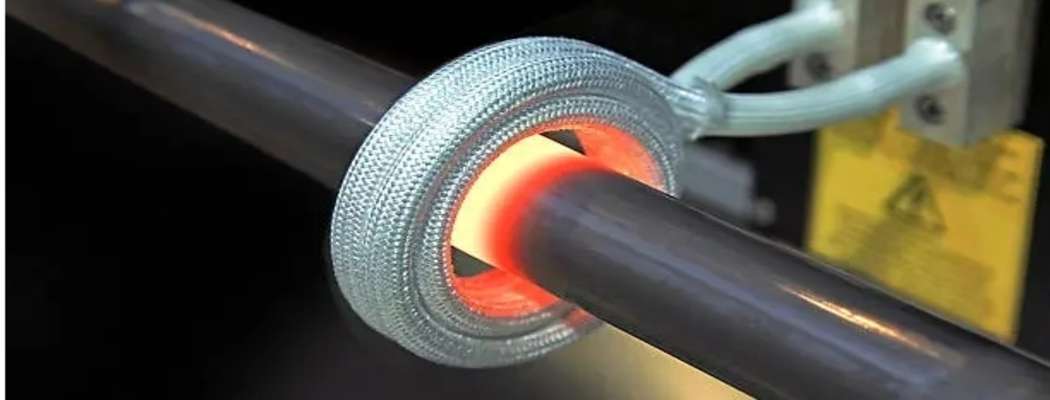

Why is induction brazing so great for this? It zaps heat exactly where you need it, fast. This avoids warping the whole part. Plus, you get incredible control. Dial in the power, frequency, and heating pattern to fit tricky shapes or fly through production lines. It makes joining complex or delicate combinations way more doable.

This blog helps you choose the right metal combinations for successful induction brazing. Now, let’s start.

Key Factors in Choosing Brazing Combinations

Choosing the right metals and filler for brazing isn’t guesswork. Several key factors directly impact your joint’s strength, reliability, and cost. Getting these right means the difference between a connection that lasts and one that fails prematurely. Let’s break down the big five you need to consider.

Thermal Expansion Match:

First up: how much your materials expand when heated. Big differences in Coefficient of Thermal Expansion (CTE) cause serious stress as joints heat up and cool down.

Think of copper and molybdenum. Their CTE gap is around 5 µm/m·°C—noticeable but manageable. Using flexible fillers like tin-silver alloys with indium helps absorb that stress.

But when you hit extreme mismatches, like ceramic-to-metal joints? That’s where clever engineering kicks in. Solutions like gradient material layers or special stress-relief joint designs become essential to prevent cracking.

Oxidation & Protection Needs

Another critical factor is your metals’ tendency to oxidize at elevated temperatures. Aluminum, titanium, and magnesium are notorious for forming tough oxide skins during heating.

Aluminum’s oxide layer (Al₂O₃) melts at a scorching 2050°C—way hotter than aluminum itself (660°C)! The persistent oxide barrier inhibits effective wetting by the brazing alloy.

How do we beat this? Grab aggressive fluoride-based fluxes. Or, work under an inert gas shield like argon. For ultra-tricky metals like titanium, vacuum brazing or ultra-pure argon is often needed to avoid dangerous hydrogen pickup (hydrogen embrittlement). Sometimes, ultrasonic vibrations help smash that oxide barrier right before brazing.

Electrical & Thermal Conductivity

Now, think about what the joint needs to do. In power electronics, electrical conductivity is king. Silver-based fillers (like BAg-8) are top performers here, hitting up to 97% IACS. Perfect for high-end circuits. But silver is pricey.

For structural joints where conductivity isn’t critical? While copper-phosphorus fillers provide significant cost advantages, their conductivity is reduced to approximately 20% IACS. Match the filler’s performance to the joint’s job.

Cost Optimization

Let’s talk budget sense. Balancing performance and cost is crucial for smart engineering. For mission-critical conductive parts (think battery terminals or sensor connections), don’t skimp—silver-copper or silver-zinc fillers deliver reliability.

For everyday structural pieces? More affordable copper-phosphorus or tin-copper fillers often do the job perfectly. And if you’re running massive production volumes? It might pay off to develop a custom filler alloy recipe to shave costs without sacrificing quality.

Wetting Control

Finally, wetting—this is how well your molten filler metal “grabs” and spreads over the base metal. Poor wetting equals a weak joint.

So, how do we make it better? Start with clean surfaces: sand lightly and use chemical cleaners. For optimal results, carefully calibrate your brazing temperature to 30-50°C above the filler metal’s liquidus point—this range typically yields the best wetting characteristics.

Tweak your filler’s chemistry too; adding tiny amounts of active elements like titanium or cerium boosts its ability to flow and bond. And never underestimate a good flux—it chemically cleans the surface during brazing, making the filler’s job much easier. Great wetting is the foundation of a strong bond.

Mastering these five factors gives you the toolkit to confidently choose metal pairs and brazing materials for reliable, high-performance joints every time.

But remember, even with the best techniques, some combinations just won’t play nicely with induction brazing. Next up, we’ll look at the metal pairs that often cause headaches and why you might want to avoid them.

Combinations to Avoid in Induction Brazing

Even with all its precision and control, induction brazing has its limits. Certain metal pairings present inherent challenges that exceed conventional brazing capabilities.

Trying to force them together often leads to weak joints, immediate failure, or costly headaches down the line. Here’s a look at the tricky pairs best left to other joining methods (or approached with extreme caution and special techniques).

The Melting Point Mismatch

Picture this: you need to join super-high-melting tungsten (3422°C) to low-melting aluminum (660°C). It’s a recipe for trouble. Standard brazing fillers struggle to wet both surfaces properly at once. Even if you find a special filler that works initially, the joint becomes incredibly vulnerable later.

Why? Any significant heat exposure during service risks melting the aluminum side while the tungsten stays solid, causing the joint to fail catastrophically. This fundamental difference is often too big to overcome reliably.

The Heat-Sensitive Material

Magnesium alloys are notoriously tricky under heat. Their grains grow super fast when they get hot. This rapid grain growth during the brazing cycle quickly destroys their strength and ductility.

While magnesium alloys can be brazed, the process demands exceptionally tight control of all parameters. You must heat it incredibly fast and cool it even faster, like hitting a bullseye with a laser pointer. In practice, the window for success is vanishingly small.

One second too long, or a few degrees too hot, and the material weakens drastically. The risk usually outweighs the reward.

The Brittle Compound Creators

Iron and aluminum really don’t get along at high temperatures. During atomic interaction, they generate rigid, fragile intermetallic phases such as FeAl₃ and Fe₂Al₅.

Imagine these as fragile glass sheets embedded within your joint. They might seem strong at first glance, but they crack easily under stress or impact, destroying the joint’s toughness.

With iron-aluminum pairings, conventional induction brazing often results in failure—and damaged components. While desperate situations might justify exotic solutions like Transient Liquid Phase (TLP) bonding, these are exceptions rather than rules.

The Thermal Expansion Nightmare

Imagine gluing glass to rubber and then repeatedly heating and cooling them. That’s the stress challenge of directly brazing ceramic to aluminum. Their thermal expansion coefficients (CTE) can differ by a massive 15 µm/m·°C or more.

As the joint cools after brazing, the aluminum shrinks significantly more than the ceramic, generating enormous pulling forces. The result? The brittle ceramic almost always cracks, or the joint itself fails.

Making this work isn’t simple brazing—it requires advanced engineering solutions. Options include flexible metallic interlayers, stress-absorbing joint designs, or sophisticated multi-layer ‘gradient’ materials. All these approaches share one goal: gradually compensating for the CTE mismatch.

Knowing what not to do is just as important as mastering the right techniques. But don’t worry! For countless common and demanding applications, there are proven, reliable metal combinations that shine with induction brazing.

Next, let’s explore some of these winning pairs and see how they deliver strong, durable joints.

Common Metal Combinations for Induction Brazing

While induction brazing offers incredible flexibility, certain metal combinations stand out as proven workhorses across industries. These common pairs, when brazed with the right techniques and fillers, deliver reliable, high-strength joints for demanding applications.

Understanding these go-to combinations—starting with joining identical metals—provides a solid foundation for mastering induction brazing projects. The best choices aren’t guesswork; they’re built on understanding material properties and proven brazing methods.

Braze Similar Metals

Induction brazing truly excels when joining metals of the same type. These combinations are often the most straightforward and reliable, forming the foundation for countless industrial applications.

Understanding these “workhorse” pairs gives you a solid starting point for successful brazing. Let’s look at the three most common similar metal combinations.

1. Copper to Copper

Copper-to-copper joints are induction brazing’s star performers in the electrical world. Think heavy-duty bus bars humming in substations or precision windings inside high-performance motors.

Why does this combination dominate? Copper’s incredible ability to conduct heat and electricity makes it a perfect match for induction’s precise, targeted heating—locking in performance right where it’s needed.

The magic shines across critical connections: robust power distribution links handling massive currents, vital grounding systems ensuring safety, and intricate motor/generator windings where reliability is non-negotiable.

Induction brazing ensures a solid, permanent metallic bond without melting the base parts—essential for keeping copper’s conductivity sky-high.

These joints form the sturdy, low-resistance backbone of modern electrical infrastructure. You’ll find them reliably carrying power in everything from renewable energy farms to next-gen electric vehicles. Their simplicity (copper meets copper) and induction’s speed make this pairing a true industry workhorse.

See details about How To Braze Copper Pipes.

2. Aluminum to Aluminum

Aluminum-to-aluminum joints are thermal management champions, forming the core of countless heat exchangers.

Think car radiators cooling engines or air conditioning units chilling buildings. These sleek, lightweight systems demand fast, reliable joining over large areas—that’s where induction brazing steps up.

Its superpower? Localized, rapid heating bonds seams without warping delicate fins or thin-walled tubes. This precision keeps aluminum’s excellent heat transfer properties intact right at the joint.

Modern production lines leverage this for high-speed, automated assembly of evaporator coils and condenser cores. You’ll find these robust joints working hard in electric vehicle battery coolers, aerospace environmental systems, and high-efficiency HVAC units.

Induction brazing delivers clean, consistent bonds that handle thermal cycling and vibration—key for reliability in demanding thermal applications. It’s the quiet force behind efficient heat movement.

3. Steel to Steel

Stainless steel joints brazed by induction form the durable backbone of demanding environments. Think chemical processing lines handling corrosive fluids, food-grade equipment requiring sterile seals, or heavy-duty exhaust systems enduring extreme heat cycles. These high-stakes applications demand joints that won’t quit.

Induction brazing delivers here by applying intense heat precisely—creating strong, leak-proof bonds without distorting thin sections or complex assemblies. This localized energy protects stainless steel’s corrosion resistance right at the joint zone, which is critical for long-term performance.

For tool steels (think drill bits, cutting blades, or high-wear components), induction brazing offers repeatable, controlled joining. It integrates hardened sections into tools without compromising their carefully engineered properties—essential for edge retention and durability under impact.

You’ll find these robust connections securing everything from pressure vessels to surgical instruments. Wherever strength, corrosion resistance, and precision matter in steel assemblies, induction brazing provides the invisible, reliable bond that holds industries together.

Braze Dissimilar Metal

Induction brazing isn’t just for matching metals! One of its superpowers is reliably connecting different metals—crucial for advanced applications where materials must meet specific needs.

These “mixed” joints come with extra challenges, but smart filler choices and clever designs make success achievable. Let’s explore three common and critical dissimilar pairs.

1. Copper Meets Steel

This dynamic duo powers critical connections where electricity meets structure. Think robust grounding grids securing substations, heavy-duty busbar supports in industrial switchgear, or power distribution clamps handling massive currents.

Copper delivers unbeatable conductivity, while steel provides structural integrity and cost efficiency—a perfect partnership for electrical infrastructure. Induction brazing shines here by creating strong, permanent bonds between these dissimilar metals without compromising their core properties.

The process applies intense, localized heat—fusing materials quickly while preventing warping in delicate assemblies. This precision ensures consistent electrical performance at every connection point.

You’ll find these hybrid joints securing safety in wind turbine grounding systems, supporting high-current rails in data centers, and forming reliable terminations in renewable energy installations. Wherever electricity flows through structures needing both conduction and support, copper-steel brazing delivers the robust connection.

2. Aluminum Joins Copper

This lightweight-conductive pairing is revolutionizing energy systems. Think battery pack terminals in electric vehicles, solar panel interconnects, and wind turbine wiring harnesses. Aluminum slashes weight, while copper delivers unbeatable current flow—a critical combination for efficiency in mobile and renewable applications.

Induction brazing steps up to create compact, reliable connections between these dissimilar metals where space is tight and reliability is paramount. Its precise heat application forms strong bonds without damaging sensitive surrounding electronics or thin battery foils.

You’ll find these joints handling high currents in EV charging stations, transferring solar energy in utility-scale farms, and connecting next-gen energy storage systems. Wherever modern power systems demand lightweight conductivity in tight spaces, aluminum-copper brazing delivers the essential link.

3. Titanium Bonds with Stainless Steel

This advanced combo enables extreme engineering where weight and reliability matter most. Think aircraft hydraulic systems, satellite fuel lines, and medical implants. Titanium offers an unmatched strength-to-weight ratio, whereas stainless steel delivers established longevity.

Induction brazing creates high-integrity bonds between these dissimilar metals. The process applies precise, localized heat—preserving material properties at the joint while preventing distortion.

You’ll find these robust, lightweight connections in rocket components and deep-sea sensors. Where high-stakes applications demand maximum reliability with minimal weight, this brazing solution delivers seamless performance.

See real applications of induction brazing.

Brazing Special Materials

Induction brazing tackles some of manufacturing’s toughest material marriages. These aren’t your everyday joints—they empower breakthrough technologies. Let’s spotlight two high-value pairs that push boundaries.

- Hard Carbide & Steel

Think drill bits chewing through rock or metal-cutting tools. That seamless carbide-to-steel bond? It’s often induction brazing’s handiwork.

BAg-24 silver filler handles intricate tooling, while copper-manganese-nickel (BCuMnNi) steps up for tools enduring extreme heat. Precision heating ensures the carbide stays hard without degrading.

2. Ceramic & Copper

Ever open an EV power module or spacecraft sensor? You’ll likely find ceramics like alumina brazed to copper inside.

Active Ag-Cu-Ti fillers make this possible, creating vacuum-tight seals essential for high-frequency electronics. Meticulous surface prep and controlled heating ensure reliability where failure isn’t an option.

These connections go beyond simple joining—they’re enablers. From more efficient electric vehicles to more durable mining equipment, brazing special materials unlocks performance where ordinary metals can’t deliver.

Conclusion

Choosing the perfect metal pair and nailing the process is what makes or breaks your induction-brazed joint. It’s the core recipe for success. Adopt an engineering mindset: evaluate material properties, operational stresses, and cost constraints. Get this balance right, and you make smart, lasting choices.

New materials are always emerging. Induction brazing isn’t standing still either—it’s constantly evolving right alongside them. This powerful combo will keep driving innovation, offering manufacturers even smarter, stronger ways to build the future.